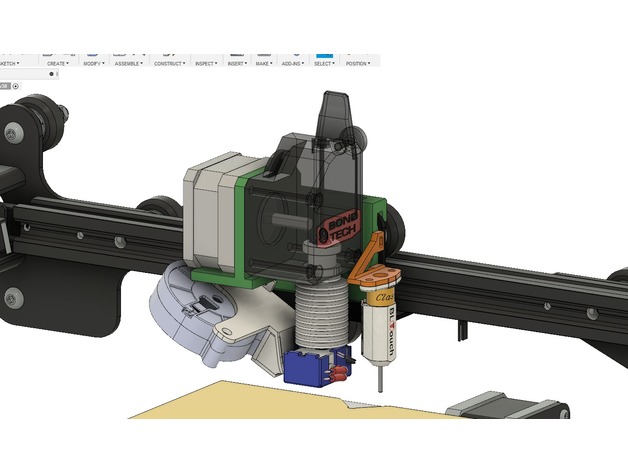

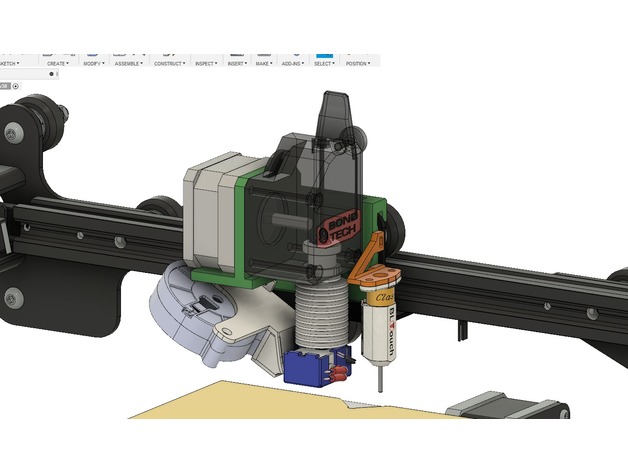

Bondtech extruder. ahintz.com: Bondtech BMG Extruder 2019-12-05

Tech Breakdown: The Bondtech QR Universal Extruder

This feature means the extruder can be optimized for specific materials. This is because it helps to reduce tool head weight. These mounts may be found at , , and. The easily accessible QuickRelease lever makes swapping filament a breeze. Twice the gears, twice the fun! Our test results can be summed up in two words - performance and reliability. It also has a device to mount Groovemount hot-ends like the E3D-V6. Quick-Release To be able to do material changes in a snap, simply activate the Quick-Release lever to release the tension and pull the material to be changed out of the extruder, keep it activated and insert the new material.

Next

Bondtech Dual Drive Extruders and Extrusion Upgrade Kits

From our free phone and email support to our easy exchange program, MatterHackers sets you up on the road to success even with just one purchase. Mounting your hotend is simple, secure, and wobble free by means of just two bolts. The extruder can use any Nema17 motor with a standard 5 mm shaft. Remove two cables for 1 of the coils of the stepper motor and let them switch place with each other. Multi-application design This extruder can be used in a Bowden or direct setups and gives you the flexibility to choose what works best for your application.

Next

ahintz.com: Bondtech BMG Extruder

The extruder is designed for 1. This means that there is virtually no chance for filament shifting, slippage or deformation during the extrusion process. Good filament tension provides additional stability to the entire extrusion ecosystem. Mounting your hotend is simple, secure, and wobble free by means of just two bolts. For suitable motors please select one of the below or use your own motor. For bowden set-ups, all you need is a bowden adapter available as an add-on , which fits into the groove mount. In addition it features an integrated hotend retention method compatible with the E3D-V6 hotends or others using the Groove Mount standard.

Next

Bondtech QR Universal Extruder

Built in fitting for the E3D hotend and fits nema17 stepper motors. Please see below for available mounts. The gears have tiny, sharp teeth on them that grab the filament from all sides to keep the flow consistent and help eradicate under extrusion. The extruder performed flawlessly in all of our use cases. One detractor is in the weight of the gearbox motor see Figure 7. In addition it features an integrated hotend retention method compatible with the E3D-V6 hotends or others using the GrooveMount standard. So are there any negatives? This means that there is virtually no chance for filament shifting, slippage or deformation during the extrusion process.

Next

Review: The Bondtech Extruder!

What I do so it does not get stuck in the extruder, is pull the filament away from the nozzle. Extrusion rate set too high The volumetric extrusion rate is a combination of layer height, extrusion width and speed. Multi-application design This new extruder can be used in a Bowden or direct setups and gives you the flexibility to choose what works best for your application. For bowden set-ups, all you need is a bowden adapter available as an add-on , which fits into the groove mount. Upon examination of the extruder, one quickly recognizes the high quality construction.

Next

Bondtech QR Universal Extruder

Bondtech Dual-Drive Our unique Dual-Drive technology delivers uninterrupted material flow without fear of grinding or slipping in even the most demanding conditions. On my , the steps per mm on the extruder is 400. Bondtech users the world over will attest that even in prints with thousands of retracts our extruders perform flawless, with unmatched precision, and zero damage or degradation to the filament. Since drive-gear diameter and gearing ratio affects the number of e-steps needed it must be adjusted in order to get the correct extrusion lenght. Built in fitting for the E3D hotend and fits nema17 stepper motors. Adjustable tension The thumbscrew tensioner allows the user to fine-tune the pressure exerted by the drive gears onto the filament. This constrained pathway and DualDrive gear system provides high extrusion force and precision filament flow.

Next

Bondtech BMG Extruder // 3D Printing Product Highlights and Review

The filament path is fully guided throughout the extruder body and the housing maintains tight tolerances to the drive gears mitigating the chances of Filament Misfeed when the hotend experiences increased back pressure or highly flexible filaments are used. The extruder is designed for 1. Also, the entire filament path, from entrance to exit, is fully constrained see Figure 5. Precision extrusion Lighter extruders enable printers to stop and start at less force, this prevents wobble when printing, improving reliability. Please see below for available mounts. The attention to detail is readily apparent in the precision of the resulting 3D printed parts.

Next

Bondtech BMG Extruder

The nylon housing provides stiffness, heat resistance and is tightly integrated with the main gearbox assembly. Recommended motor current setting: 1. Multi-application design This new extruder can be used in a Bowden or direct setups and gives you the flexibility to choose what works best for your application. The filament path is fully guided throughout the extruder body and the housing maintains tight tolerances to the drive gears mitigating the chances of Filament Misfeed when the hotend experiences increased backpressure or highly flexible filaments are used. Multi-application design This extruder can be used in a Bowden or direct setups and gives you the flexibility to choose what works best for your application. Enjoy :- Print Settings Printer Brand:.

Next

Bondtech i3 MK3 BMG Style Geared Extruder by bobblejot

The attention to detail is readily apparent in the precision of the resulting 3D printed parts. For the latest 3D printer news, and make sure to. The extruder uses the Groove Mount standard see Figure 4 which allows for direct placement of or. Quick-Release To be able to do material changes in a snap, simply activate the Quick-Release lever to release the tension and pull the material to be changed out of the extruder, keep it activated and insert the new material. This extruder only supports 1. .

Next