Coop extra skogn. COOP EXTRA LEVANGER 2020-01-28

Coop Extra Skogn

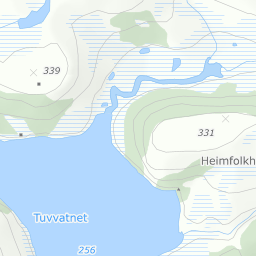

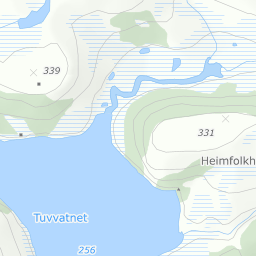

In the midst of construction the issue of building a second machine was raised. Transshipment of lumber in heading for Fiborgtangen With the deregulation of the electricity market in the 1990s, Norske Skog was concerned regarding its purchasing price of power. The standard newsprint was at the time 52. One of the issues the company had to address was the location of the mill. There was ample access for fresh water. This included the 4 hectares 9.

Next

Coop Extra Skogn

Newsprint prices fell dramatically during the early 1990s, so that the company went with a loss despite the cost cuts. The increased population was key to the development of Skogn reaching a population of 2,400 and has helped develop the village and its services. Plans were therefore gradually articulated within the Norwegian Forest Owners Association and its chapters. This led to the establishment of the Forest Owners Industrial Committee Nordenfjelds on 8 December. An agreement secured 300 per year of electricity from. In addition to being located centrally in the forest-rich Trøndelag, it was near routes to the Swedish forests in.

Next

Norske Skog Skogn

Formal work commenced in 1972 and the corporate assembly approved the plans on 5 December 1977, giving the board freedom to proceed as was deemed favorable. The opening of the mill caused the area to experience rapid expansion. Lysblink has a of 7,500 tonnes, and has a deck area of 4,070 square meters 43,800 sq ft. The second source of pulp is from recycled paper, sourced both domestically and through import. The company also worked on plans to build a container port at Fiborgtangen. Formal talks were initiated at a meeting held between the regional forest owners associations on 14 June 1958, initially discussing the possibilities of establishing a mill in.

Next

Norske Skog Skogn

The ministries gave a preliminary support to the forest owners' proposal, allowing funding for further investigations. The commission recommended unanimously on 27 January 1961 that the mill be organized as a , that it receive one paper machine with an annual output of 100,000 tonnes, a mechanical pulp mill with an annual production of 80,000 tonnes and 20,000 tonnes of pulp produced through the. In addition to serving the company's own needs, it hoped to establish a facility which would allow the port to serve all of Trøndelag, as well as transit freight from in Sweden. The site was located next to the , and was on the ice-free part of the , allowing for good transport. Fiborgtangen produced 519,000 tonnes in 2003. The acquisitions resulted in Nordenfjelske becoming a , where the factor at Fiborgtangen merely was the largest mill. The reason for avoiding a cooperative proper was that it would have difficulties raising the necessary capital.

Next

Gratis alternativt telefonnummer til Coop Extra Skogn gratis kontakt, ring gratis og fra utlandet Coop Extra

A pulp mill was considered, based on recently abandoned proposals for one in , a site found to be too remote. By then the scale had increased and the capacity increased to 170,000 tonnes. The Norwegian Forest Owners Association approved the plans on 20 March. Sites were considered in , Steinkjer, , Skogn, Stjørdal and. This caused Nordenfjelske to also start negotiating an acquisition with , the largest sawmill in the region, situated in Namsos. The lumber harbor was dredged of 200,000 cubic meters 7,100,000 cu ft of earthwork, while on the opposite side of the site a 235-meter 771 ft port was built. Total building area measured 31,107 square meters 334,830 sq ft , of which the paper machine halls filled 15,000 square meters 160,000 sq ft in a hall measuring 240 by 58 meters 787 by 190 ft.

Next

Coop Extra Skogn

The ensuing decade saw a gradual reduction in the demand for newsprint. The annual meeting elected as the board's chairman. Fifteen homes had to be abandoned to build the mill, which took over an area of 40 hectares 99 acres. Prices were set through negotiations between forest owner associations, organized by , and the industry. Representatives for the forest owners traveled in February 1961 to Finland to inspect cooperative mills there.

Next

Norske Skog Skogn

In their original configuration the two paper machines had a production of 430 meters 1,410 ft per minute. Supply was provided through 3. The initiative for establishing a major industry for lumber was therefore both based on the desire for proximity as well as the desire for the forest owners themselves to own the mill. Contracts were predominantly signed for one year at a time. The central and southern associations had sufficient capital to simply pay out, while forest-owners Nordensfjells were charged a six-percent fee on all lumber for five years to secure sufficient equity. Although there was a slight opposition from the authorities, 97 percent of Van Severen was bought in late 1970, followed by a take-over of Ranheim on 1 July 1971.

Next

Norske Skog Skogn

The commission was set to consider the mill's location, the amount of lumber it needed, processing techniques as well and financing and ownership issues. This allowed more marginal areas to be logged. The from the lumber is extracted and used in as on-site heating. Meanwhile, Nordenfjelske started looking at the supply of , of which it needed an annual supply of 40,000 tonnes. Several of the small pulp mills in Norway were struggling through the 1970s. However, the increased consumption was initially met also with increased production, through several new paper machines in Europe. Proposals for a mill came from the , who wanted a major industrial facility to buy in.

Next

Gratis alternativt telefonnummer til Coop Extra Skogn gratis kontakt, ring gratis og fra utlandet Coop Extra

A primary concern was to concentrate the purchasing of lumber in Central Norway. There was an overproduction of chemical pulp and this could be bought cheaply and easily. This included 18 hectares 44 acres of agricultural land. Import of recycled paper and export of newsprint have been subcontracted to. The main bio sources are bark from lumber and recycled slam from the decontamination processes from process water. There was also a shallow bay which could be filled in to store lumber. The company was listed on 's list of non-listed companies on 1 July 1969, followed by a main listing on from 2 January 1970.

Next

COOP EXTRA LEVANGER

The initial agreement called for the plant to be completed by 1996. After buying and , the company took the name Norske Skog in 1972 and gradually expanded beyond their inaugural mill at Skogn. Nordenfjelske was barred for entering the cartel and instead chose to ally with. Various proposals were made, including expanding , or building new mills either in or. This would be supplied through a proposed from. Several politicians proposed that a new paper machine should be located elsewhere, and locations such as Namsos and were mentioned as sites, as these had recently lost pulp mills.

Next