Glass molde. How to Make Glass Slumping Molds 2019-12-07

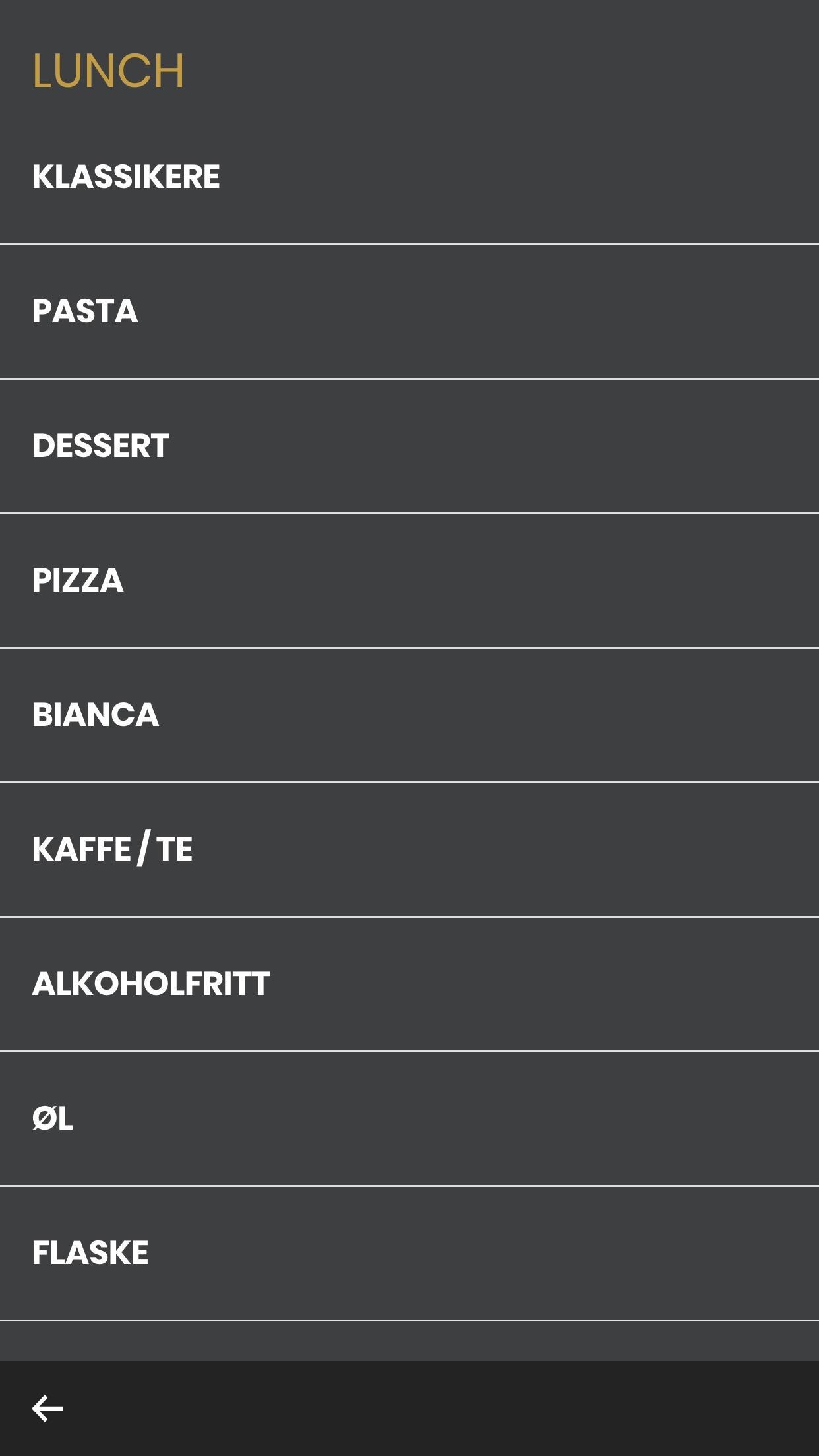

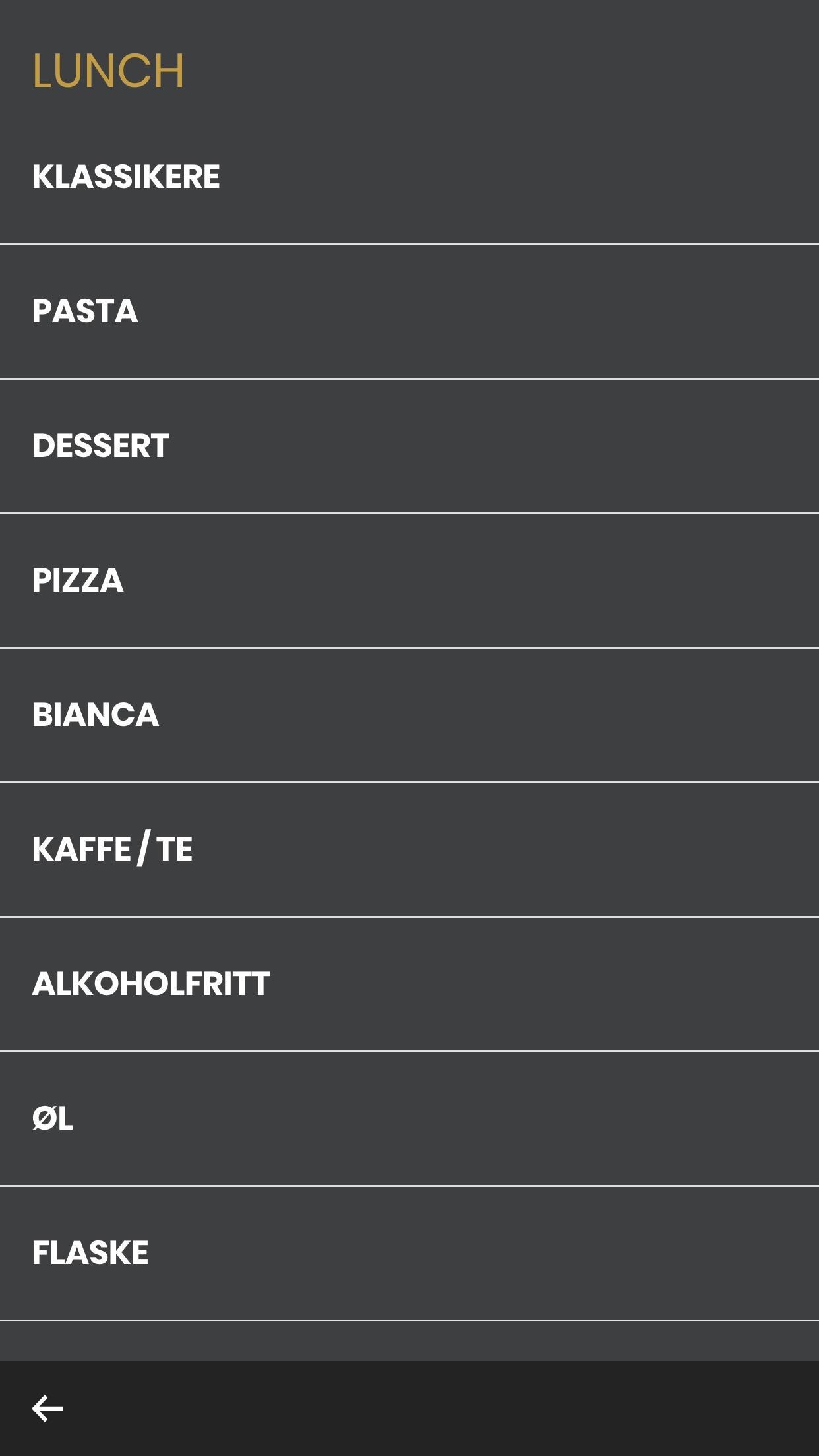

GLASS RESTAURANT & BAR, Molde

Use a hake brush to apply the primer to the mold. The table below gives an overview of achievable manufacturing tolerances in precision glass moulding at different companies. Let the mold try a little and lift it off the bowl. You can buy glass casting molds online or check at the local glass refinery if they sell them. To achieve a homogeneous layer thickness, the mould's position has to be changed during coating.

Next

Blue Fire Molds

This will ensure that an even flow of heat passes around your mold. In addition, mould materials include aluminium alloys, glasslike or vitreous carbon, silicon carbide, silicon nitride and a mixture of silicon carbide and carbon. Buy a specialized kiln washing product online. The series production can then be executed without further need for measurements. Kiln washing products are very effective at cleaning molds. The primer will act as a glass separator on the mold, preventing the glass from binding to the mold. Molds for glass slumping are surprisingly easy to make.

Next

Precision glass moulding

You can use the cap on top of your glass' container to gently pour the glass into the mold. The precious metal films such as PtIr Platinum, Iridium coated on the ceramic substrates can effectively reduce the interface reaction between the glass and substrates. Note: These are handmade, so slight variations in size are expected—be sure to measure your mold before cutting glass to fit. Place the kiln in a large warehouse or a garage with the garage door wide open. We will send you a notification when it is ready to view. Use a diamond pad or a grinding stone to make it smooth and get rid of any blemishes. Get a kiln that's big enough to fit your mold into.

Next

Blue Fire Molds

Let the kiln fully cool down. Create four holes near the bottom. The air won't get trapped and the glass will melt from the bottom. For smaller production volumes, the preforms have to be manufactured by mechanical material-removing steps from blocks or slices of raw glass. For the right element geometry, it can enable economical production of aspheric lenses up to 60 mm in diameter and more than 20 mm thick. A commonly used material in mould making is. This indicates that severe interface chemical reaction occurred and resulted in the loss of transparency in glass appearance.

Next

Blue Fire Molds

Moulding concave forms with small centre thickness is difficult due to sticking of the moulded part to the mould occurring as a result of the different thermal expansion coefficients. Use a tissue to dab the primer to see if it's dry. Cover the bowl with cloth so that it will release from the clay, Press the clay it against the bowl so that the clay assumes the exact shape of the bowl. It's safer to let it dry at room temperature. Besides that the time for transport and handling has to be taken into account in the planning of the process. After finishing the process the glass lenses are removed from the holder and the holder is cleaned by sand-blasting or other techniques. This process is only suitable for high production volumes.

Next

Glass molds

Don't touch the mold or reach into the kiln until the outside is cool to the touch. The key is to make the mold out of the right material which will withstand the 1,200 degree temperature in the kiln. Create a flat, steady foot on the mold so that it will stand straight in the kiln, even with glass loaded on top. For precision moulded lenses such measurements are only necessary for a small amount of sample lenses in order to qualify the tool. You can find a hake brush at the local hardware store. Apply the first coat of primer to the mold. Mould materials such as steel can be used for moulding low-Tg-glasses whereas high-Tg—glasses require a high-temperature mould material, such as.

Next

Slumping molds from Creative Ceramics

When blow drying, turn the blow dryer onto a high setting and hold it near the mold for 1 minute or so. Moldy glass takes away from the simple beauty of a vase of flowers or an open window. This difference between the temperature it fired at and the temperature an hour later is the cooling rate per hour for the kiln. Casting glass is difficult and requires some specialist machinery. Clean your mold with a toothbrush. Fill the mold with your glass. For bigger groups we sell 2 - and 3 - course dinners packages and we use fresh local ingredients to make a menu that suits you.

Next

Slumping & Draping Molds

The process is also known as ultra-precision glass pressing. There are two basic types of molds in glass slumping. For the lens design it should be considered that the lens has to be mountable in measurement systems. Convex surfaces are easier to manufacture. When the kiln is firing, it will be extremely hot, so avoid touching it directly.

Next

Slumping molds from Creative Ceramics

Therefore, research activities aim at substituting PtIr with cheaper materials. This will burn out any impurities and harden the clay for handling. Please try again later or book directly on {provider}. The mold materials also have to be suitable for machining into the precise surface profiles. For more information, see our overview:.

Next

Slumping molds from Creative Ceramics

This means that especially fast cooling can not be applied. Slipcast from a specially formulated clay body, these molds have an exceptionally smooth surface, accept kilnwash uniformly, and do not crack under repeated use if handled properly. You should add enough glass to the mold so it slightly overflows above the top of the mold. You can buy this product at the local tiles or ceramics store. Especially the cathode of the machine has to be cleaned. Use gloves to open the paper towel to protect yourself from glass shards.

Next