Steam powered. Steam power plants 2020-02-08

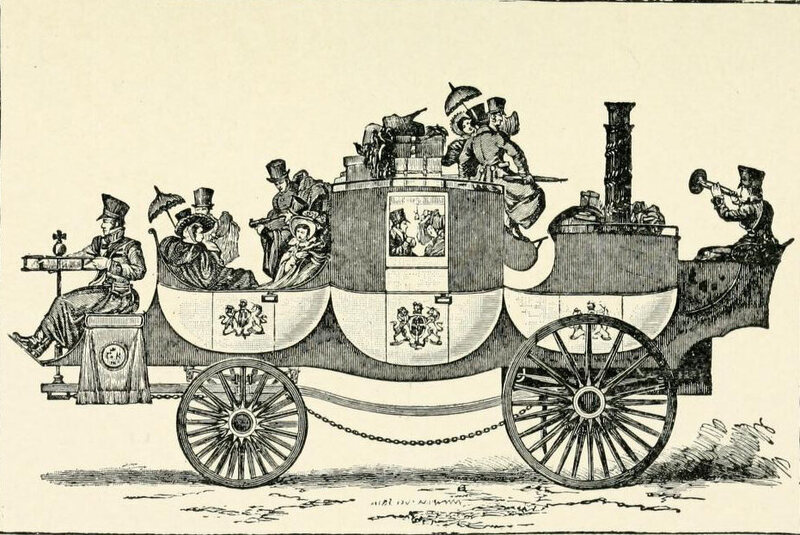

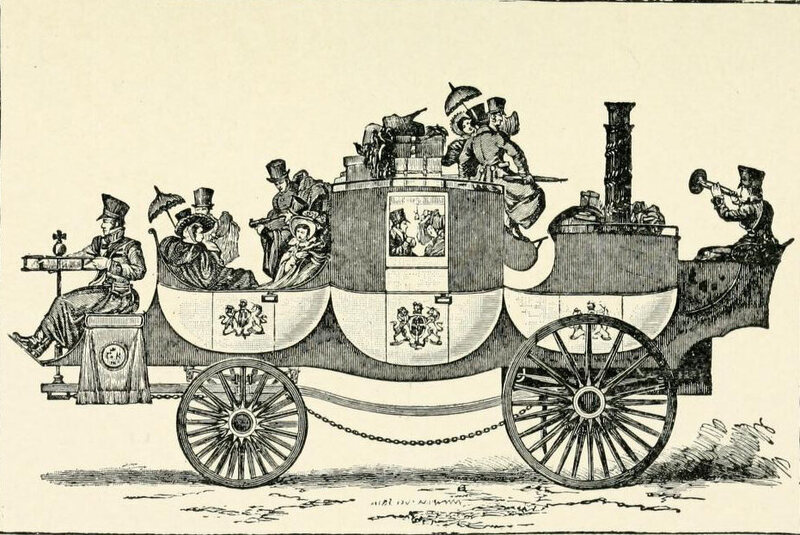

Steam car

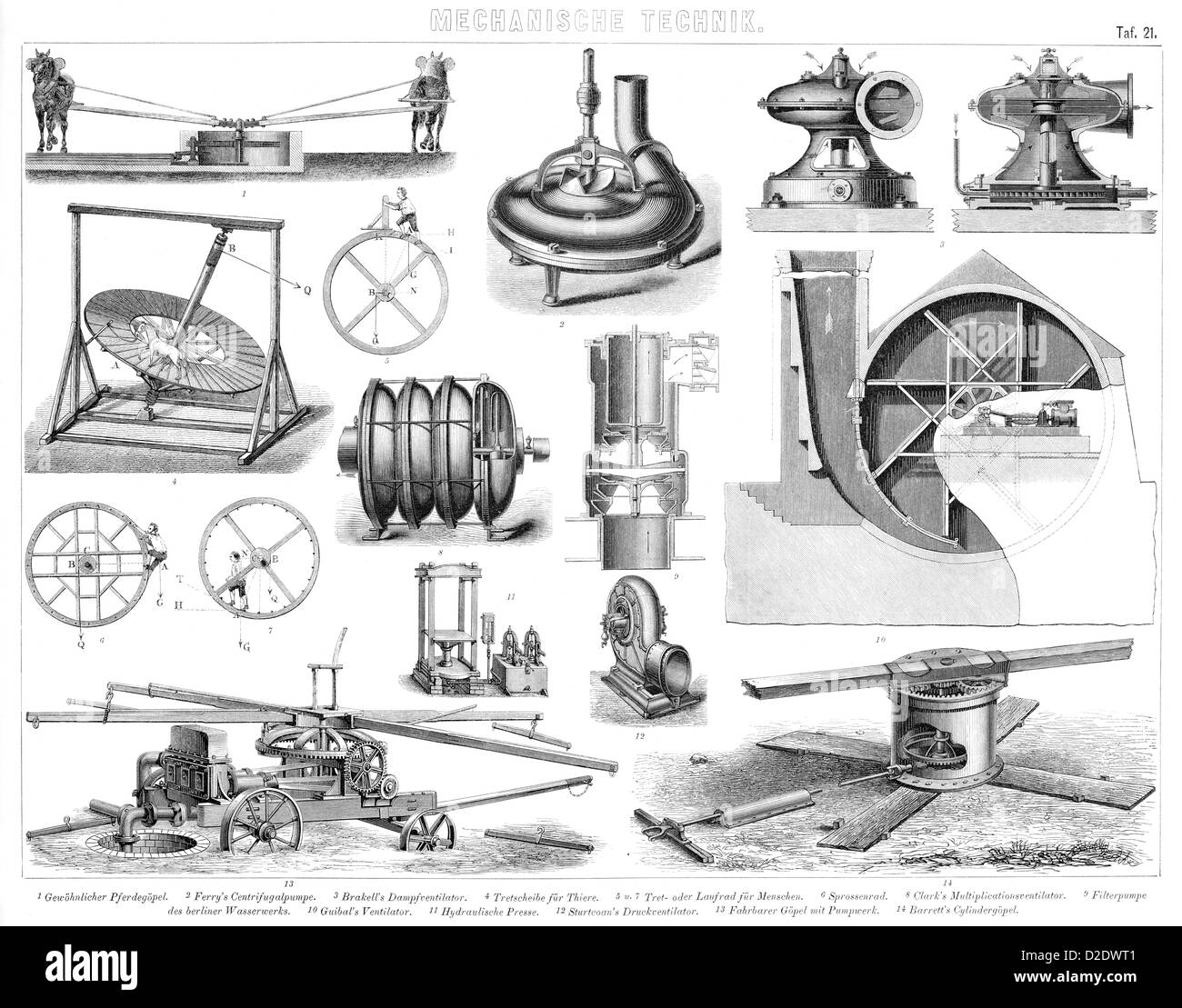

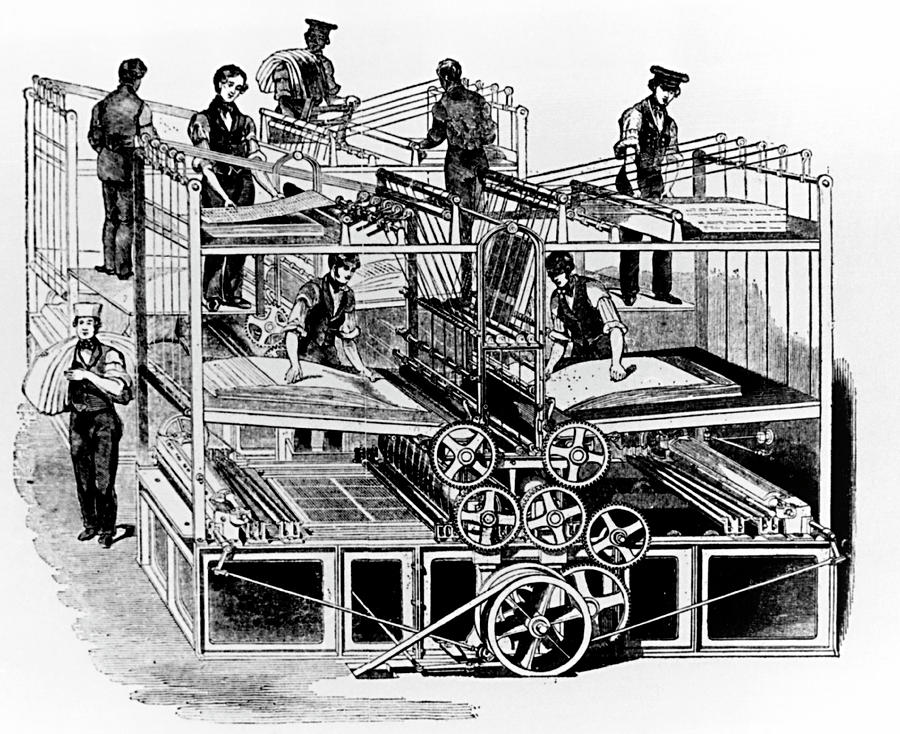

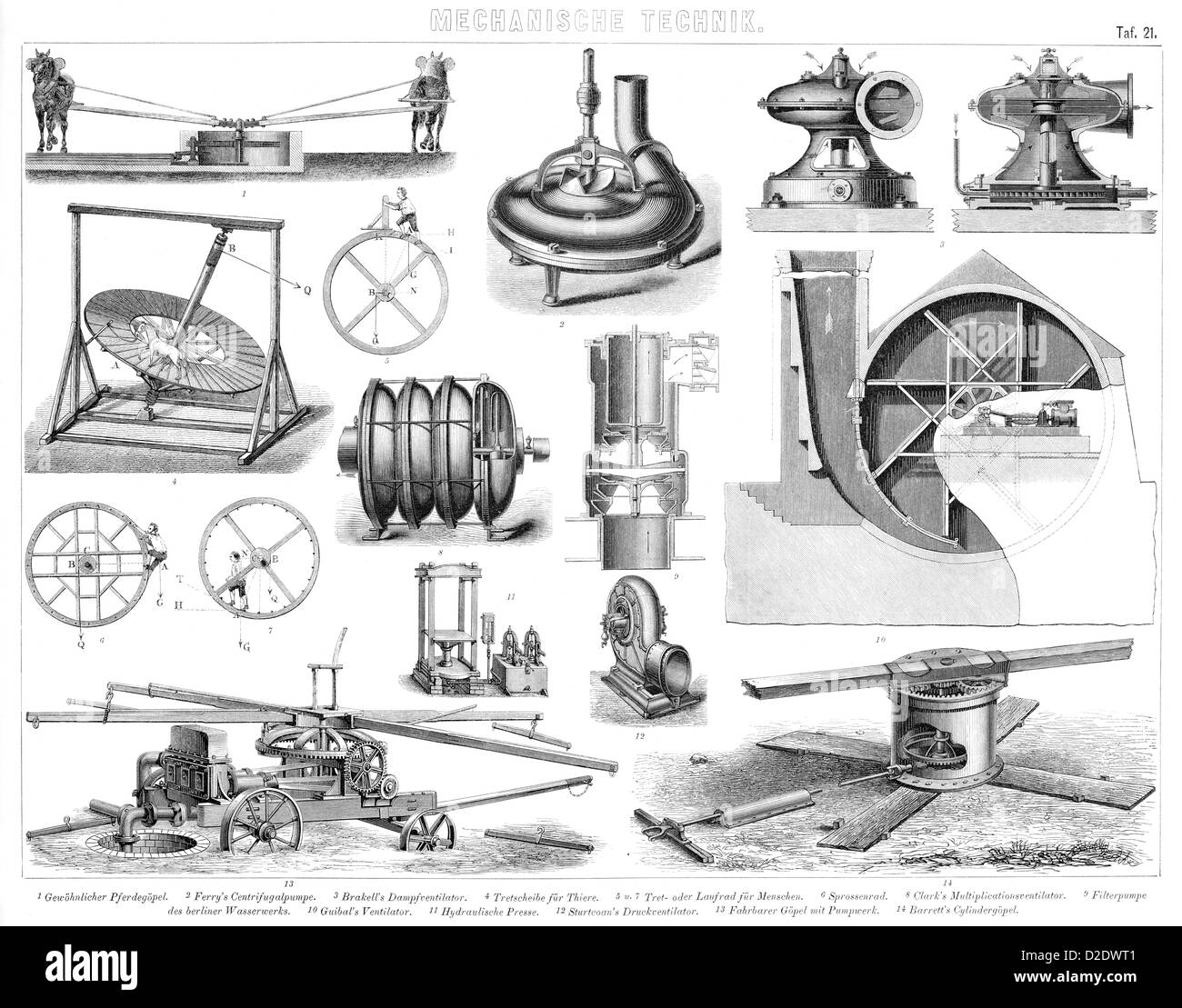

Nuclear Turbine Island Product Catalog Our turnkey turbine island offering includes the critical power generation equipment— from the turbine generator package, to the services, pumps and control systems. Another estimated 60,000 horsepower was being utilized by engines that were created by manufacturers infringing on Corliss's patent, bringing the total horsepower to roughly 180,000. There is no set schedule, but usually we try to push updated translations live with any Steam and game update. Their engines were therefore arranged with the piston axis vertical. These events are controlled by valves often working inside a steam chest adjacent to the cylinder; the valves distribute the steam by opening and closing steam ports communicating with the cylinder end s and are driven by , of which there are many types. You can only remove your own suggestion use the button offered under your suggestion.

Next

Steam

Early valves could be adjusted by engine drivers, leading to many accidents when a driver fastened the valve down to allow greater steam pressure and more power from the engine. With the steamboat this time was reduced drastically with trips ranging from twenty-five to thirty-five days. In 1784, , a inventor, built a prototype steam road locomotive. In the case of model or toy steam engines, the heat source can be an electric heating element. With all this torque they can very quickly. Duty is the number of of delivered by burning one 94 pounds of coal.

Next

Steam

The speed of a steam car is controlled by the alone and the engine never. Will I be removed, if I don't do anything? Y-S-T engines divided the low-pressure expansion stages between two cylinders, one at each end of the engine. Main article: The industrial use of steam power started with in 1698. Lack of expansive working, or any means of control of the , is also a serious problem with many such designs. Trevithick was a man of versatile talents, and his activities were not confined to small applications.

Next

Steam Controller BLE

Connect to a different stored wireless receiver by pressing Steam+Back. Early mills had run successfully with water power, but by using a steam engine a factory could be located anywhere, not just close to water. Engines equipped with a condenser are a separate type than those that exhaust to the atmosphere. After that, steam-driven pumps could be used to remove water from the deep mines of the day. It was, however, superseded by the British invention where speed was required, for instance in warships, such as the , and. They could also carry heavy loads with ease.

Next

Steam Client Beta

With the installation of 1,000+ industrial boilers and 6,000+ industrial steam turbines under our belts , we can help ensure the reliable operation of your industrial plant while working with you to lower operating costs as well. You can get access to awesome benefits like; studio work videos, see new music videos first, and help them make their next songs and album! Siemens has modified its core components to address these new requirements while bringing added value to our customers. You can see there's much work to be done, and we're glad you're here to help - Your contribution to Steam translation will impact users worldwide. Cornish engines were used in mines and for water supply until the late 19th century. When prompted, press Y + Steam Button on your Steam Controller to make it discoverable. Steam escapes and typically can and have in the past caused great loss of life. Some very large engines even allowed for applications as large as 1,400 horsepower.

Next

Steam power

The Steam user community consists of over 125 million people around the world who run Steam in one of 26 languages. Pumping the working fluid in liquid form during the cycle requires a small fraction of the energy to transport it compared to the energy needed to compress the working fluid in gaseous form in a compressor as in the. The mean horsepower for all Corliss engines in 1870 was 100, while the mean for all steam engines including Corliss engines was 30. However, the most interesting question is: What happens at the construction site after the turbine package has been delivered. Railroad tracks, which were already in use in mines and various other situations, became the new means of transportation after the first locomotive was invented. In 1698 patented a pump with hand-operated valves to raise water from mines by suction produced by condensing steam.

Next

Steam

Yes, before you can suggest translations you will have to undergo a two-step application procedure after you log on above. A History of Industrial Power in the United States, 1780-1930, Vol. By this means, the simple-expansion uniflow engine gives efficiency equivalent to that of classic compound systems with the added advantage of superior part-load performance, and comparable efficiency to turbines for smaller engines below one thousand horsepower. The development of the was a very important early element of the Industrial Revolution. A south Wales town has begun months of celebrations to mark the 200th anniversary of the invention of the steam locomotive.

Next

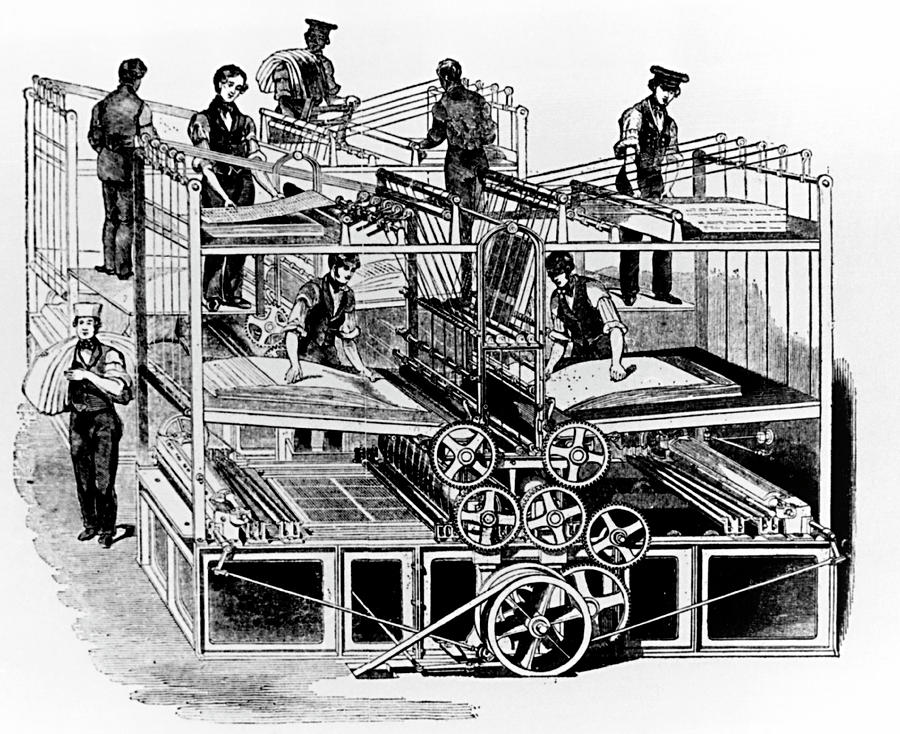

Steam power during the Industrial Revolution

While variations in standards may exist in different countries, stringent legal, testing, training, care with manufacture, operation and certification is applied to ensure safety. As high-pressure steam is admitted into the working cylinder, much of the high-temperature steam is condensed as water droplets onto the metal surfaces, significantly reducing the steam available for expansive work. They were powered by air pressure pushing a piston into the partial generated by steam, instead of the of expanding steam. A rudimentary device was described by in in 1551 and by in Italy in 1629. The cylinder casting contained steam supply and exhaust ports. By the 19th century, stationary steam engines powered the factories of the. The most efficient performance—that is, the greatest output of work in relation to the heat supplied—is secured by using a low condenser temperature and a high boiler pressure.

Next