Ultrasonic flow sensor. Ultrasonic Technology Flow Meters 2019-12-06

ULTRASONIC FLOW METER

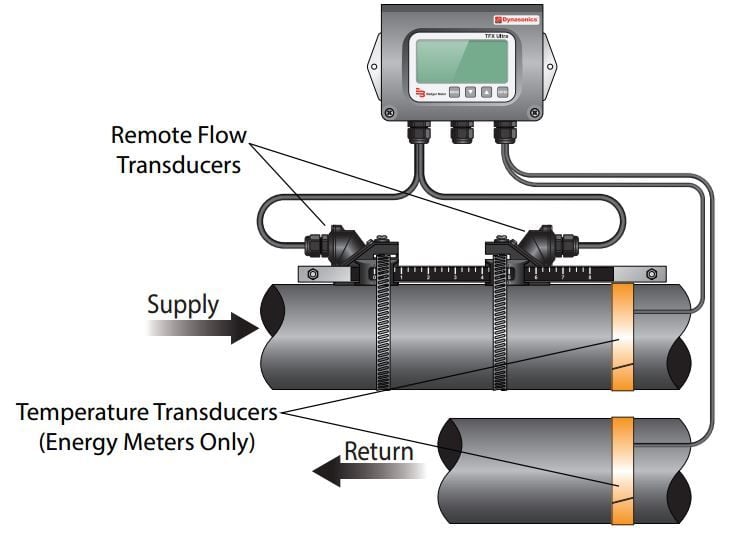

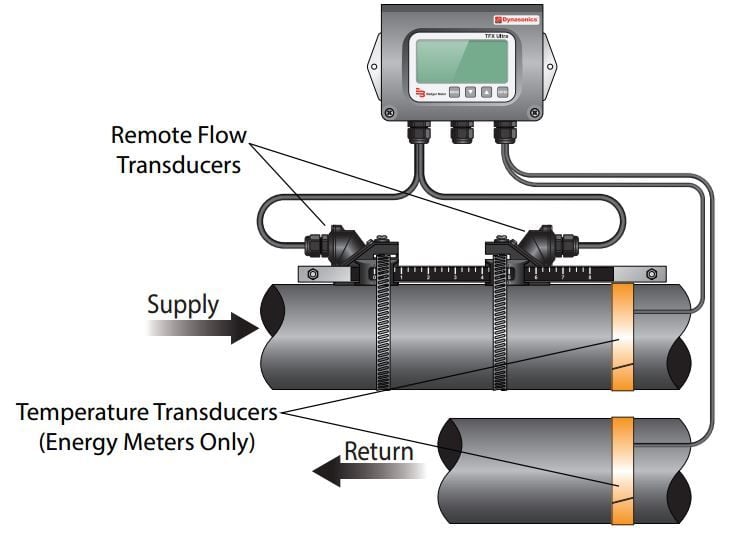

With highly accessible top-side mounting options that don't require confined space entry, installation and maintenance is quick and simple, making this an extremely economical approach. Ultrasonic flow meter with totalization These ultrasonic flow meters are well-suited for full pipes of liquid that contain at least 100 ppm of 100 microns or larger suspended particles or gas bubbles for pipe sizes 0. Ultrasonic flowmeters use this principle to accurately measure the volume of many liquids and gases — and also to derive parameters like density and viscosity. Doppler shift measures the difference in frequency of the sound wave reflected off gas bubbles or particles in the flow stream and is suitable for aerated or dirty liquids. Transmission or contrapropagating transit-time flow meters can be distinguished into in-line intrusive, wetted and clamp-on non-intrusive varieties. Inaccurate or unknown glycol water compositions may lead to deviations of up to 30% of the volumetric flow.

Next

Ultrasonic Technology Flow Meters

Ultrasonic Doppler flowmeters that clamp onto the outside of a pipe operate non-invasively, without moving parts. We provide quality solutions that increase energy efficiency and reduce installation cost with the fastest delivery times in the industry. They are also ideal when used in combination with a flume or weir. The portfolio expansion of an Ultrasonic Flow Sensor featuring patented glycol compensation technology is a true testament of our ongoing commitment to innovation. Ultrasonic meters are ideal for wastewater applications or any dirty liquid which is conductive or water based but will generally not work with distilled water or drinking water. This distance is either the zero level no flow present or a specific level in the flume or weir.

Next

Ultrasonic Flow Measurement

Transit-time meters are best used for measuring the flow of clean liquids and, as a result, are the most popular type of ultrasonic meter. The , each function by way of two different technologies. The non-invasive sensor has no contact to the medium and is particularly suited for applications with strict hygienic standards. There are also built-in acoustic discontinuities in copper, concrete-lined, plastic-lined, and fiberglass-reinforced pipes. Carefully engineered applications using such flowmeters have had reported installed accuracy within 0.

Next

How Does an Ultrasonic Flow Meter Work

In 1842, Christian Doppler discovered that a stationary observer perceives a sound to have shorter wavelengths as its source approaches, longer wavelengths as its source recedes. When traveling in the same direction as a flowing medium, ultrasonic waves move faster than waves traveling against the flow. Installation Ease Multi-point wet calibration enables hassle-free installation and accurate flow measurement from start-up. This intelligent approach places the transducer parallel to the flow surface within an engineered enclosure that contains a 45° reflector. Ultrasonic waves that advance through water will be transmitted slowly when going against flow and conversely, will be transmitted quickly when going along with flow.

Next

Hach US9000 Ultrasonic Sensors

In addition, to provide an accurate volumetric flow rate, all ultrasonic flow meters require the pipe to be full. This metering technique utilizes the physical phenomenon of a sound wave that changes frequency when it is reflected by moving discontinuities in a flowing liquid. The most popular form of this utilises the principle known as either transit time or time of flight. Don't assume, though, that the centerline reading is automatically more accurate. Ultrasonic sensors are not affected by chemicals, grease, suspended solids, or silt in the flow stream. An ultrasonic flow meter is a type of that measures the velocity of a with to calculate volume flow.

Next

Ultrasonic Flow Meters For Noninvasive Or Inline Measurement

Ultrasonic Doppler flow meters put this frequency shift to work in so-called dirty liquids containing acoustical discontinuities; suspended particles, entrained gas bubbles or turbulence vortexes. The transit time corresponds to the distance between the face of the sensor and the surface of the water. Watch the video to learn more! Insufficient or unreliable water temperature readings could distort the heat coefficient by up to 18%. If the flow approaching the flume has been properly conditioned and the flume properly set, either condition is acceptable. They are also used in chemical, pharmaceutical, food and beverage, metal, mining, pulp and paper and wastewater industries.

Next

Ultrasonic Flow Measurement

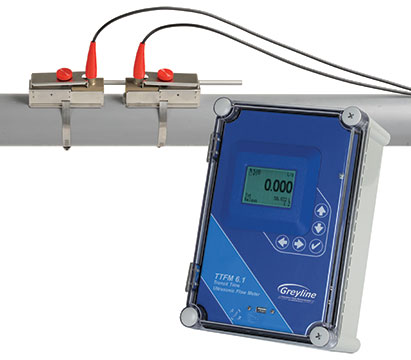

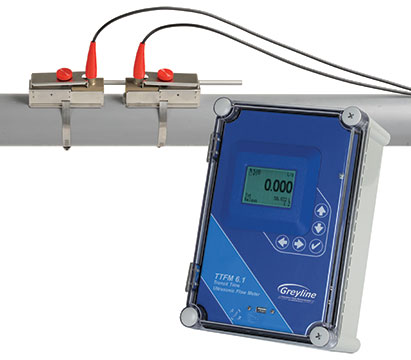

Ultrasonic sound is transmitted into a pipe with flowing liquids, and the discontinuities reflect the ultrasonic wave with a slightly different frequency that is directly proportional to the rate of flow of the liquid. Transit time ultrasonic flow meters are ideal for clean liquid applications such as water and oil. The transducer generates an ultrasonic signal that passes through the pipe wall into the flowing liquid; the transmitter converts the difference between its output and input frequencies to electronic pulses. The Doppler effect explains why one hears rising pitch in the blowing horn of an approaching car. How to install an ultrasonic flow meter Both Doppler and transit time flow meters are designed to clamp onto the outside of a pipe without breaking the line or interrupting the flow. The development of an inline flow sensor that uses ultrasonic transit-time technology to automatically measure and compensate for glycol concentration is a huge advance in thermal energy measurement.

Next

How Does an Ultrasonic Flow Meter Work

In the dual sensor version, the transmit crystal is in one sensor body, while the receive crystal is in another. The accuracy of an ultrasonic flow meter relies on proper mounting. Ultrasonic flow meters are non-intrusive devices that use acoustic vibrations to measure the flow rate of liquid. To optimize every operation, Siemens offers a comprehensive selection of inline ultrasonic and clamp-on ultrasonic flow sensors, transmitters and complete flow systems. This dramatically decreases flow meter accuracy to within only ±20% , and, in most cases, clamp-on meters will not work at all if the pipe is lined.

Next

SONOFLOW Sensors

Consideration must be given to the lower limits for concentrations and sizes of solids or bubbles, and the liquid must flow at a rate high enough to keep the solids suspended. Comprehensive diagnostic functions The comprehensive diagnostics functions feature an automatic air-bubble and water presence detection. Ultrasonic flow meters are inferential meters that uses ultrasonic technology to measure the velocity of an acoustically conductive liquid moving through it. Clamp-on Doppler flow meters are subject to interference from the pipe wall itself, as well as from any air space between the sensor and the wall. Whichever ultrasonic technology you choose, Siemens offers you a bit more: more innovations, more simplicity in use, more performance — and more confidence in your measurements. They vary greatly in purchase price but are often inexpensive to use and maintain because they do not use , unlike mechanical flow meters.

Next