Big rep. BigRep GmbH 2019-12-05

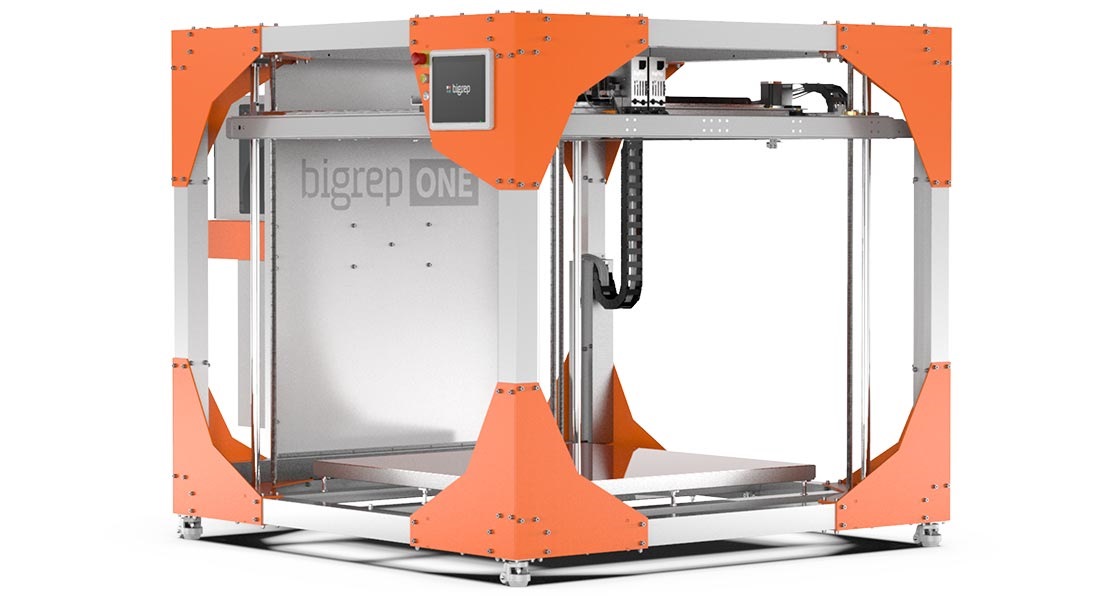

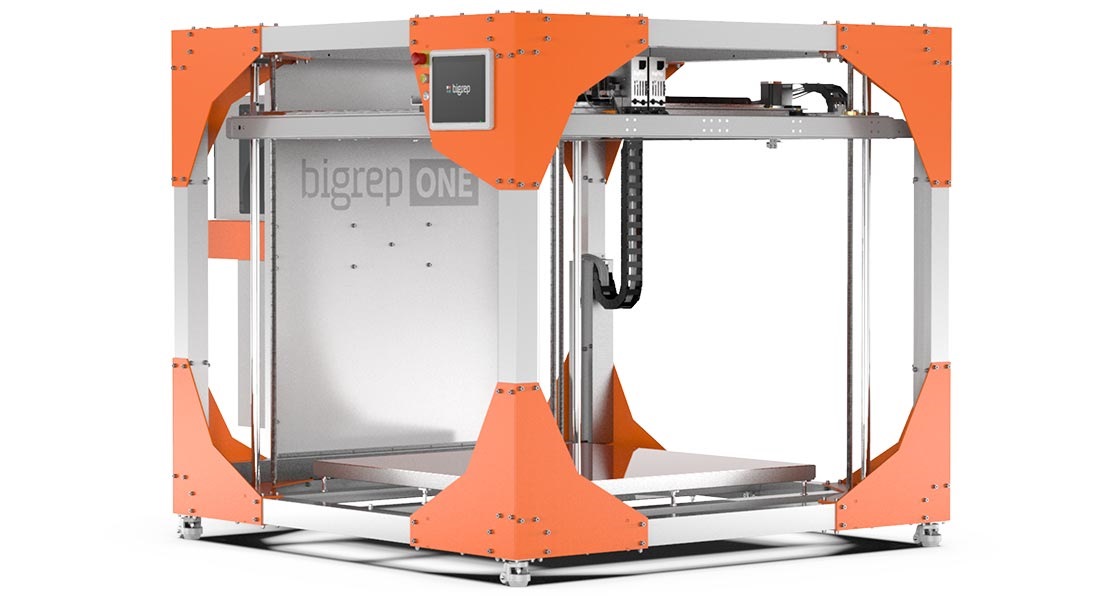

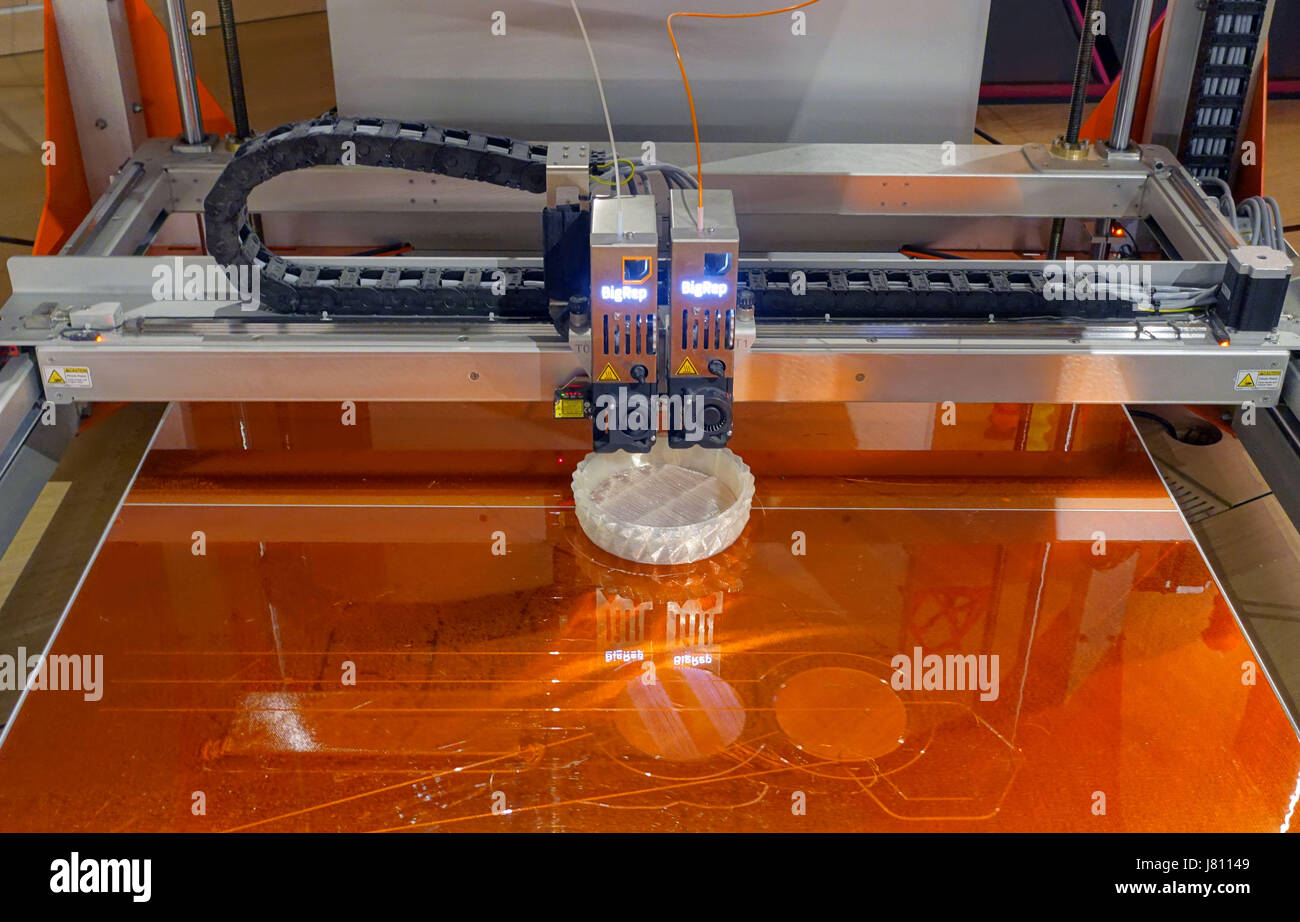

BigRep One

Formnext is taking place in Frankfurt, Germany until November 16th. We offer a range of translucent and opaque colors inspired by the spirit of our birthplace, the city of Berlin. . German-engineered for better quality, higher speed, and increased safety, when using room temperature materials. A heated build chamber provides a controlled, high-temperature environment of up to 200° C in the chamber and 220° C in the print bed. The Bigrep Pro takes 3D printing to the next level.

Next

Large

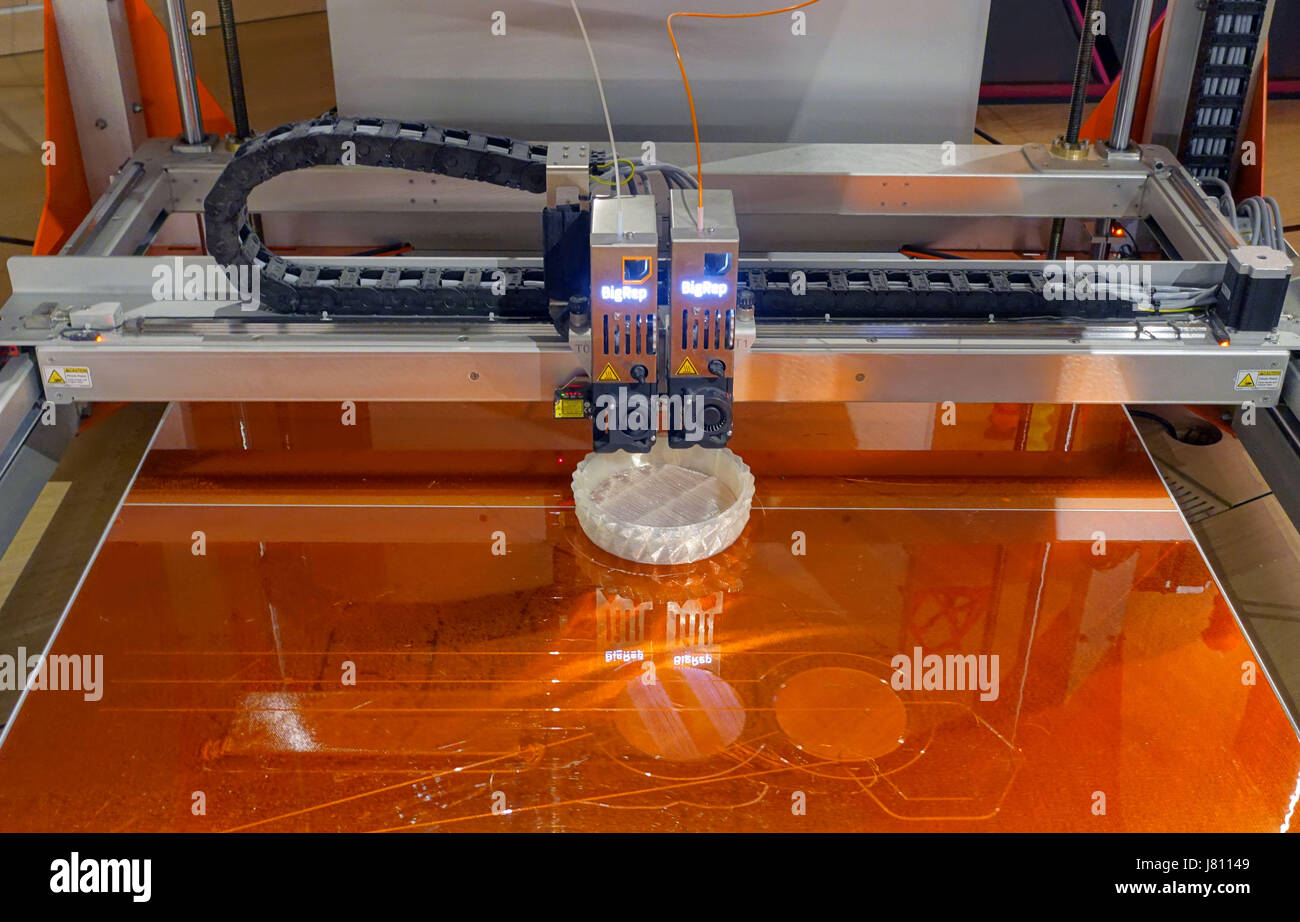

This mode may set cookies on your computer once you click on the YouTube video player, but YouTube will not store personally-identifiable cookie information for playbacks of embedded videos using the privacy-enhanced mode. In the future it can additionally be integrated with sensors to monitor part status and provide maintenance or replacement information — simply scan the part and print a replacement. Air circulation fans within ensure air flow for uniform temperature throughout the filament cabinet, and the cabinet stores up to four filament spools. Next is Bigrep One, This printer is considered one of the best 3D printers available in the market for printing ample size objects. However, this expansion is similar for every moment of time hence the exponential law - the expansion of a local volume is the same number of times over the same time interval , and is characterized by an unchanging, small , effectively ignored by any bound material structures.

Next

Large

It also presents an alternative to large warehouses and remote production facilities, creating a more sustainable production process. The technology is designed to take full advantage of the new 3D printing materials BigRep is developing in partnership with. Image via BigRep Subscribe to the for the most comprehensive coverage of Formnext 2019. Build with German engineering technology; Bigrep 3D printers are manufactured to provide you round the clock 3D printing with unfailing reliability. A heated print bed is mounted with polyimide foil for better adhesion during the 3D printing process, and an integrated inductive sensor allows for semi-automatic leveling. They are then packed in low-humidity conditions for safe storage, promoting predictable extrusion independent of whether you use them today or weeks from now.

Next

BigRep showcases 3D printed autonomous electric podcar 'LOCI' at Formnext 2019

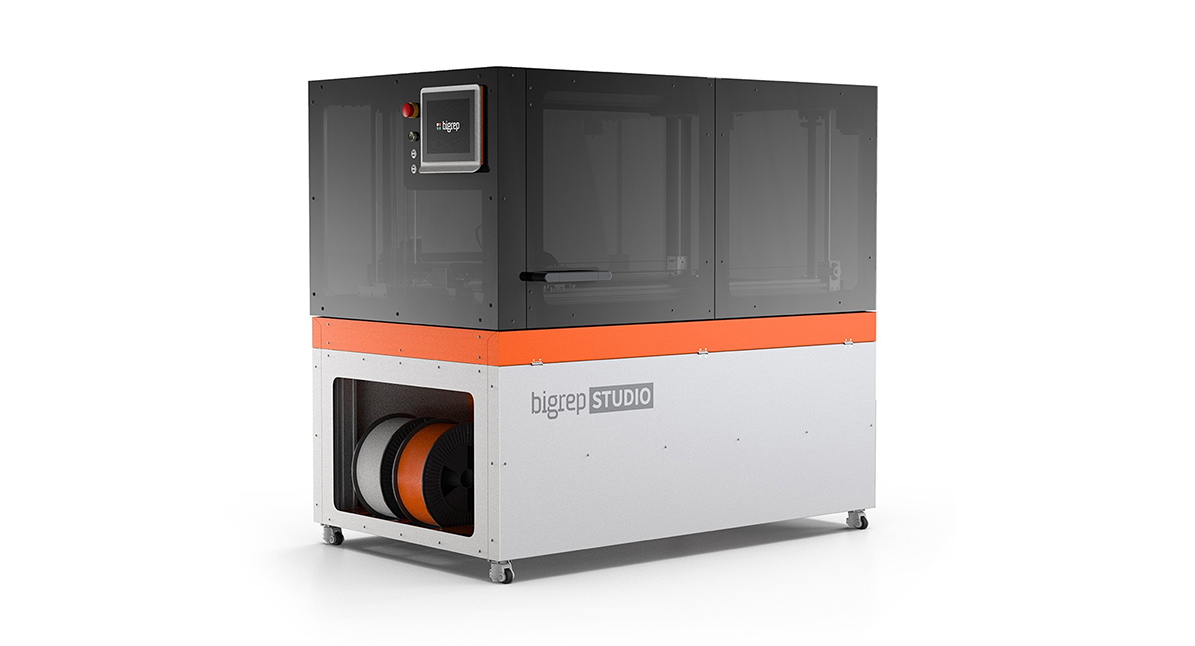

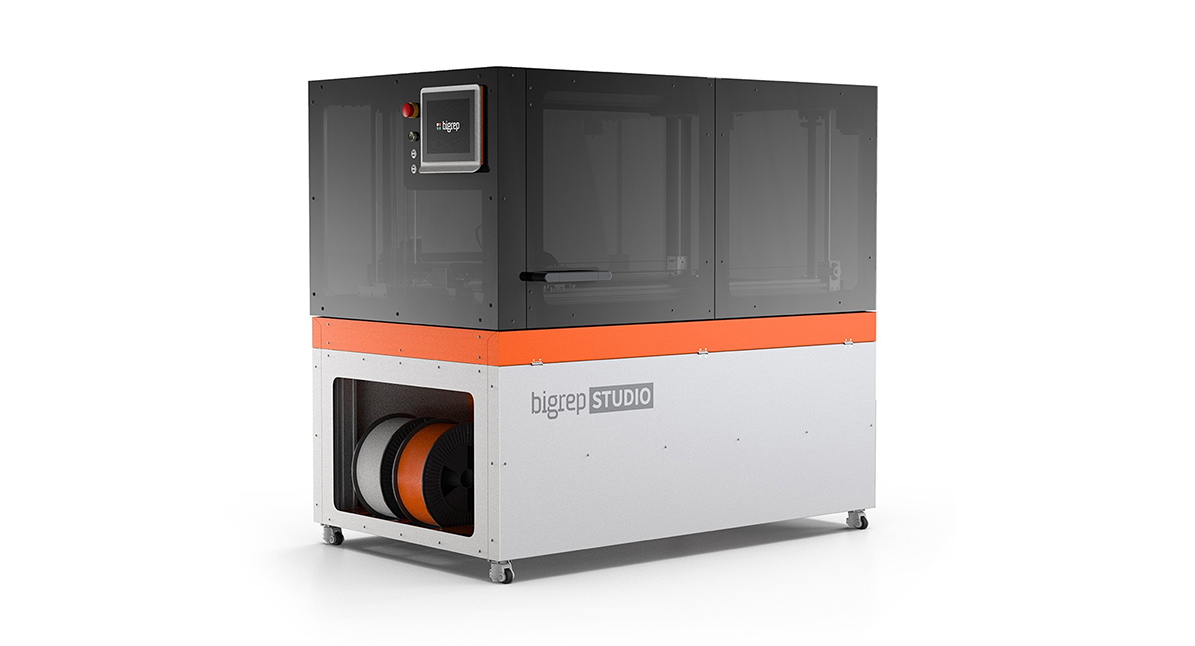

By contrast in the Big Rip scenario the Hubble constant increases to infinity in a finite time. The next-generation 3D printers will allow designers and engineers to create functional prototypes, composite tooling, end-use parts and small-number serial production. Visit for a selection of roles in the industry. The next in the line up of Bigrep series is a professional 3D printer for printing large scale industrial objects. The first in the series of 3D printers manufactured by Bigrep is — Bigrep Studio, This printer is a compact 3D printer designed to focus on high speed and efficiency. It features 14 unique 3D printed parts, and measures 850 mm x 1460 mm x 2850 mm, with the largest component coming in at 1000 x 600 x 700 mm.

Next

Industrial 3D Printer BigRep PRO

With a fast-heating print bed and temperature-controlled filament chamber this high-resolution large-print workhorse produces incredible results with high-quality materials. BigRep 3D printing filaments are created under carefully controlled conditions to guarantee uniform diameters and consistent composition. The type that could cause this hypothesis is a constantly increasing form of dark energy. This chip can be scanned using a mobile device to identify parts. In the last minutes, stars and planets would be torn apart, and an extremely short amount of time before the Big Rip, would be destroyed. The Nera e-motorbike by BigRep. You can also stay connected by following us on and liking us on Looking for a career in additive manufacturing? This can include daily work commutes, campus transport, local deliveries and airport, and train departures.

Next

Industrial 3D Printer BigRep PRO

About 60 million years before the Big Rip, gravity would be too weak to hold the and other individual galaxies together. We then assume that you have an interest for Simple Sign and the content on this site. Comes including a high-resolution 1mm nozzle for highly precise prints. The dual extruder equipped with two 0. Approximately three months before the Big Rip, the or systems similar to our own at this time, as the fate of the Solar System 22 billion years in the future is questionable would be gravitationally unbound. We use this to better understand how people interact with our site and to see their journey through the website.

Next

Large

The possibility of sudden rip occurs only for hypothetical matter phantom energy with implausible physical properties. When the size of the observable universe becomes smaller than any particular structure, no interaction by any of the can occur between the most remote parts of the structure. Such cases are usually individually manufactured by hand, limiting their availability. The industrial-grade quality machine has a print volume of 500 mm x 1000 mm x 500 mm that enables continuous printing of large objects in a space-saving package. The dual extruder equipped with two 0. This printer lets you print large 3D parts conveniently. Its award-winning, German-engineered machines are establishing new standards in speed, reliability and efficiency.

Next

BigRep showcases 3D printed autonomous electric podcar 'LOCI' at Formnext 2019

From the cool tones of the Grosser Wannsee to the warmer hues of the landmark Rotes Rathaus, our unique color palette opens the doors to free innovation. For example, special tires can be equipped for different terrains. Both are present at the show in render concept versions. The enclosed print envelope maintains a controlled temperature and boasts a print volume of 500 mm x 1000 mm x 500 mm, enabling continuous printing of large-format objects with nylon and other engineering-grade materials. BigRep has designed and manufactured a machine that prints with engineering-grade materials to ensure users can manufacture the applications they need, in large scale.

Next

Large

If the dark energy in the universe increases without limit, it could overcome all forces that hold the universe together. Galaxies would be destroyed as stars separate from the main black hole. During , BigRep presented a similar application of its 3D printing technology. At the time the Big Rip occurs, even spacetime itself would be ripped apart and the scale factor would be infinity. Capable of print times up to 60% faster than standard BigRep extruders with the same resolution.

Next