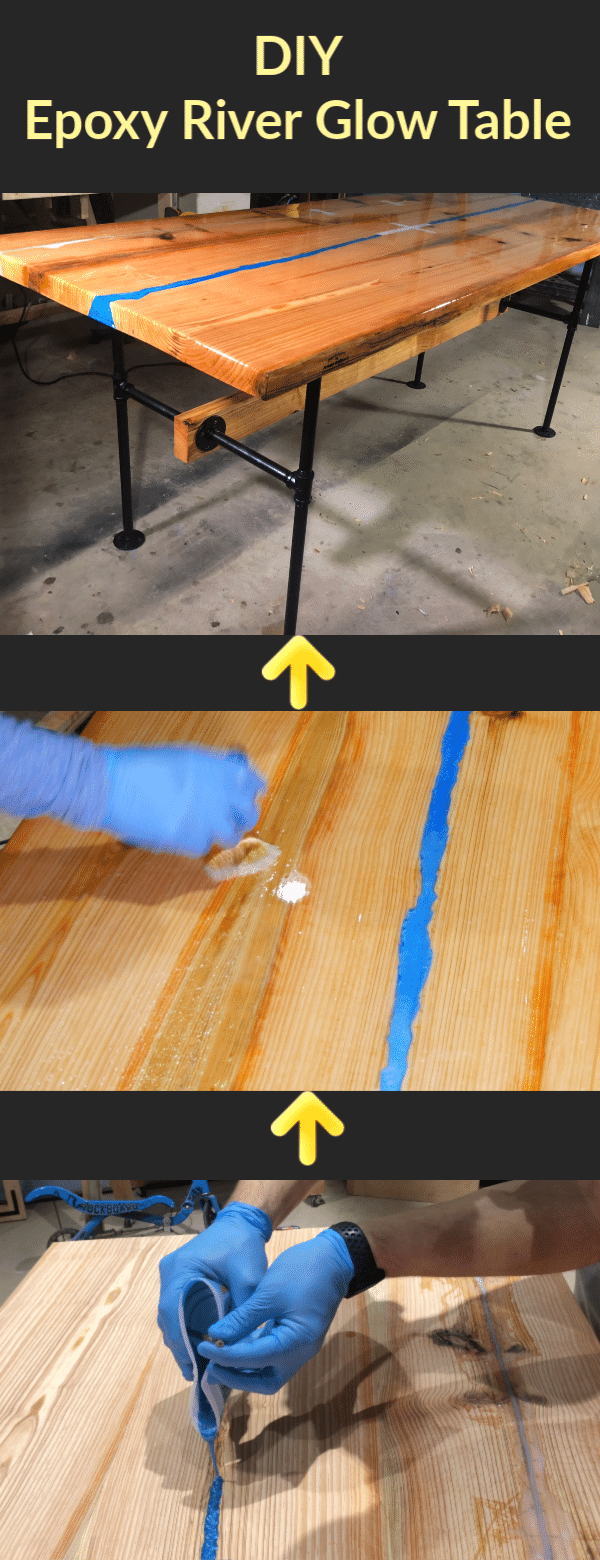

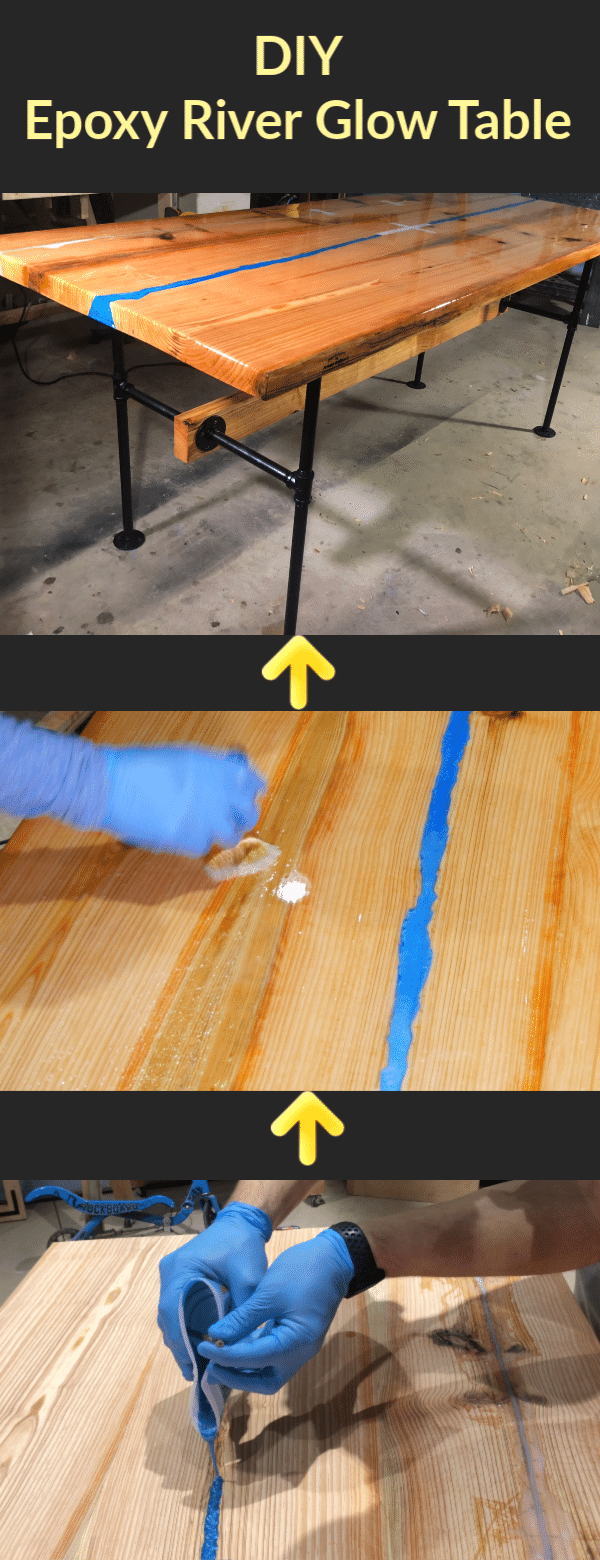

How to make epoxy table. How to Make a Resin Table Top 2020-01-24

Pour Me A River [Table]: Epoxy Resin Gets Artsy

This will hold in the epoxy. Make sure that this mixture is brushed evenly on your table so that all air pockets will be sealed. Slow one hour to dry. At first, the river tables were rather uncomplicated, but when Greg made a complex glass pattern in wood, ideally imitating the incorrigible natural lack of wood, the man received the same voluminous rivers with ornate banks and crystal clear waters. Do not forget to carry out grinding, polishing surfaces.

Next

50 epoxy river table designs for unusual interior

Making a resin table top is something that just about anybody can do. We have been immersed in the world of River Tables recently, which are currently taking over Instagram. You can also do a lot with it to make your table look completely unique and fit your style as well as your décor. To use the thread taps, I drilled a pilot hole of the correct size on the drill press. If the fillers are too light, stick them to the bottom, otherwise, they will float. If there are any unwanted drips that do not come off with the masking tape then you can sand them off. To make it as convenient as possible to mix the material, select the appropriate dishes for this.

Next

How to Color Epoxy Resin, Our Top Pigment Choice

Then sand it down with 120 grit followed by 220 grit. The epoxy live edge side table looks great! Every wrong step is spoiled stuff. Then I played around until I found the line I wanted and marked both ends for the cut. Following each pour, go in with your hand-held blowtorch and heat any areas where there might be trapped air bubbles. You can to estimate how much epoxy will be necessary.

Next

How to Color Epoxy Resin, Our Top Pigment Choice

You will also need to be able to reach all sides of your table with ease. Finishing a wood project with some sort of wax or topcoat seals in the epoxy, and gives a glossy finish to the work. Generally, about one drop of acrylic for around 4 ounces of resin is a good mixture. But notable can be compared with an amazing table made from a type of Vyaza or from a slab cut of a tree trunk, the edges of which in the finished product remain intact with built-in blue ponds. If you are going to create such a product, you must first clean the surface, remove fat from it.

Next

How to Make an Epoxy Resin River Table

Your table is going to have to be completely clean before you begin. If liquid gets into the mixture, the tabletop may be damaged. We advise pouring a base layer to seal the underside of the wood - this will help to minimise air bubbles during the main pour. Its size will depend on how much epoxy you need. I used 8mm by 50mm Dominos, and used two in each corner. I made her a desk awhile back, but that was too bulky to lug around.

Next

DIY Resin River Table Using Clear Epoxy Casting Resin and Wood: 12 Steps (with Pictures)

I especially recommend a kitchen torch as they are cheap, super safe feeling she you use them, and then you can make creme brûlée later as your reward. This might be a little difficult to explain in words but this effect is achieved by using two different materials; wood and resin. Build a box with plywood. If you check on the countertop epoxy website, you will find a chart to help you with square footage coverage. A layer of 1-2 cm will become hard in 24 hours, and 1 mm will not dry in a few days.

Next

How to make Epoxy resin table step by step

The fabrication of a river table using epoxy resin occurs in several stages. Here is another , but you will have to pour multiple thinner coats to keep it from cracking. So as a part of our collaboration I created this photo-heavy epoxy resin coffee table. I am looking for a printer that can print on fabric, cardstock, photoes, etc. Had my process worked out in my favor I would have been done. The sides should come off easily enough by themselves.

Next

How To: DIY Resin Epoxy Table

Allowit to dry per the manufacturer's recommended curing time between coats. So you might try their resin if you do more and not have to wear the mask. Learn more about how to make your own river table. It is available to all comers. Aim to slightly overfill the river channel, then leave the resin to fully cure! We love trying to do budget-friendly, beginner-friendly takes on different projects. Cracked wood: It looks very interesting wooden surface, corroded bark beetles or fungus. Dried epoxy resin is able to maintain the original volume - this is one of its main advantages.

Next